Unveiling the Artistry: Exploring the Intricacies of Screen Printing

The Process of Screen Printing

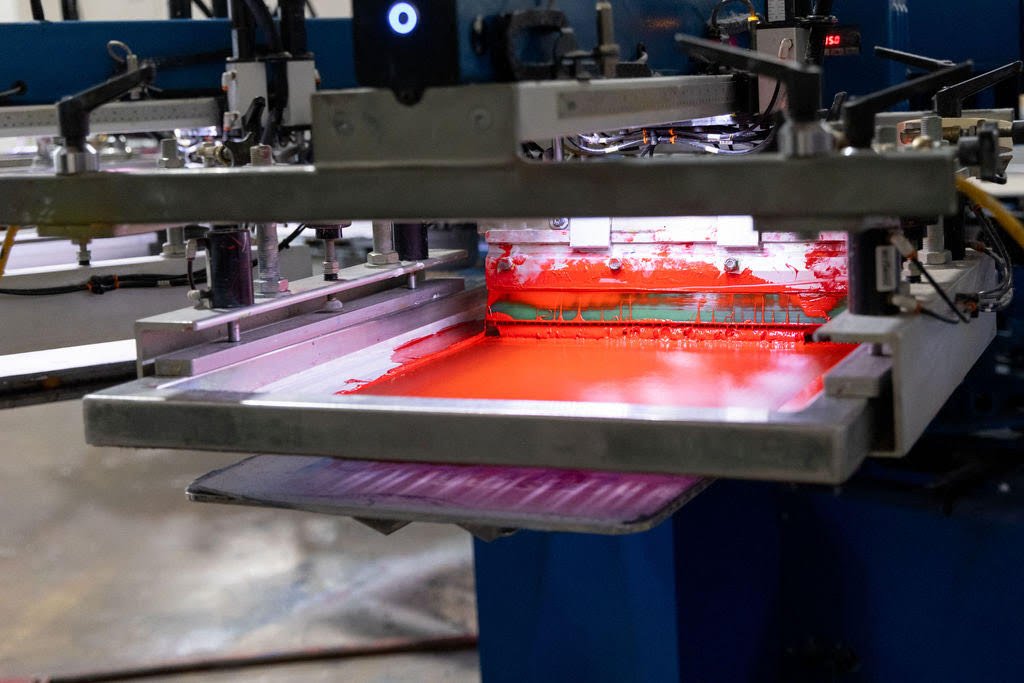

Screen printing is a fascinating and intricate process that involves several meticulous steps to create vibrant and long-lasting designs on various surfaces. The process typically begins with creating a stencil, also known as a screen, typically made of a fine mesh material such as silk or synthetic fibers. This screen is then stretched over a frame and coated with a light-sensitive emulsion. Once the emulsion is dry, a design or image is placed on top of the screen through photographic exposure or hand-drawing with special inks. The exposed screen is then washed, which leaves behind a stencil that allows ink to pass through onto the chosen material, be it fabric, paper, or even metal. The final steps involve carefully applying ink to the screen, which is then pressed onto the target material using a squeegee. This process is repeated for each color in the design, with precision and alignment crucial to achieving a crisp, vibrant result. After each color is applied, the material is typically cured to set the ink, ensuring the design's longevity.

The Advantages of Screen Printing

Screen printing is preferred against various alternative printing methods for several compelling reasons. Firstly, it offers unparalleled durability and longevity, making it ideal for designs that need to withstand wear and tear, such as clothing or outdoor signage. Moreover, screen printing excels in color vibrancy and opacity, allowing for brilliant and vivid results on dark or colored materials, which may pose challenges for other techniques like digital printing.

Screen Printing on Clothing

The printer must carefully load each garment onto the press, position it accurately, and ensure the screens align perfectly. With the garment in place, the ink is applied across the screen, transferring the design onto the fabric. This process is repeated for each color in the design, with precise registration critical to avoid color overlap or misalignment. Afterward, the printed garment is typically cured through heat, ensuring the ink bonds properly and remains durable. The process demands a keen eye for detail, expertise in color mixing, and a steady hand to ensure each garment receives a high-quality, vibrant, and long-lasting print.